In today’s fast-paced manufacturing industry, efficiency and flexibility are key factors in achieving success. One area where these factors play a crucial role is in the labelling of products. Whether it’s bottles, containers, or jars, having an accurate and efficient labelling process is essential. This is where double side sticker labelling machines come into play. These machines are designed to apply self adhesive label to two sides of your products simultaneously, offering multiple labelling options and enhancing efficiency. In this comprehensive guide, we will explore the features, benefits, and applications of double side sticker labeling machines.

1. Introduction to Double Side Sticker Labelling Machines

Double side sticker labelling machines are revolutionizing the labelling process in various industries. These machines are specifically designed to apply self adhesive label labels to two sides (front and back) of your products simultaneously. This not only enhances efficiency but also provides multiple labelling options for full flexibility. Whether you are in the food and beverage industry, pharmaceuticals, cosmetics, or any other industry that requires accurate and efficient labelling, double side sticker labelling machines can meet your needs.

2. How Do Double Side Sticker Labelling Machines Work?

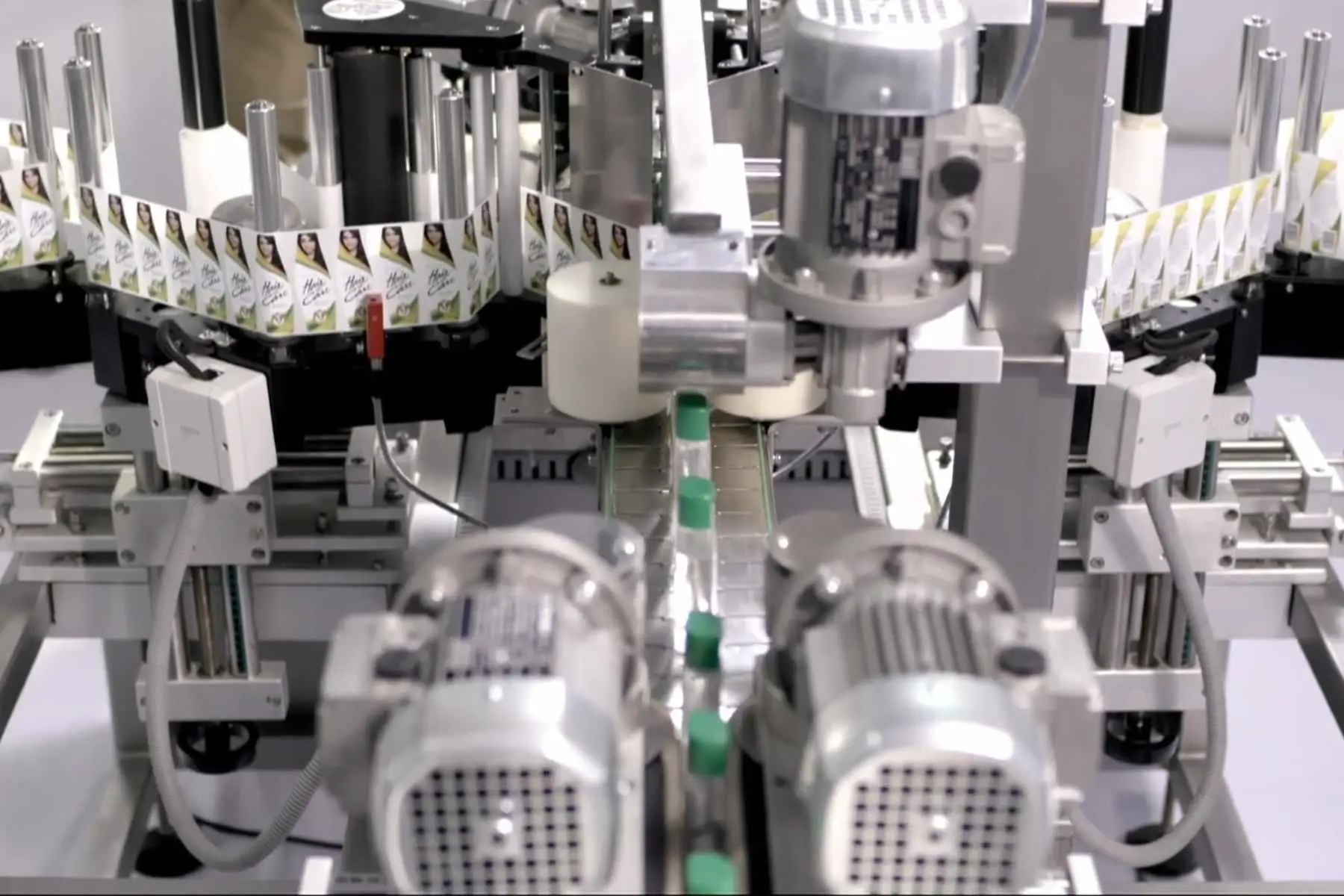

The operation of double side sticker labelling machines is simple yet effective. Your product is moved through the conveyer of the linear label machine, while two pressure-sensitive label applicators press the labels onto two sides of the container. This offers more opportunities to add important information to your product labels as well as branding details. The machines utilize advanced technology such as PLC and touch screen control, servo motor control, and automatic length checking to ensure accurate and precise label placement.

3. Benefits of Double Side Sticker Labelling Machines

Double side sticker labelling machines offer numerous benefits for manufacturers. These include:

3.1 Enhanced Efficiency

By applying labels to two sides of the products simultaneously, double side sticker labelling machines significantly increase the speed and efficiency of the labelling process. This allows for higher production rates and reduces the overall time required for labelling.

3.2 Flexibility

Double side sticker labelling machines provide flexibility in labelling options. Whether you need to label the front and back of a product or apply labels to different sides of irregularly shaped containers, these machines can accommodate various labelling requirements.

3.3 Accurate Label Placement

With advanced features like automatic length checking and servo motor control, double side sticker labelling machines ensure precise label placement. This eliminates the risk of misaligned labels and enhances the overall appearance of the product.

3.4 Cost-Effective

By streamlining the labelling process and reducing the need for manual labor, double side sticker labelling machines can help in cost savings for manufacturers. The increased efficiency and accuracy also minimize the chances of label wastage, further reducing costs.

4. Worldpack’s Double Side Sticker Labelling Machine

Worldpack offers a range of double-sided linear labelers that are well-known for their industry-leading efficiencies and reliability at high linear line speeds. These machines are suitable for high-speed production lines and can be customized to meet specific application needs.

4.1 WPM NOVA Labelling System

The WPM Nova labelling system is designed to apply both front and back panel labels to a variety of products at adjustable speeds. It offers ultimate flexibility and precise label placement for different shapes and sizes of containers.

4.2 Double side labelling machine with WPM Nova Labeler

WPM Nova Labeler utilizes a twin belt product handling system and can apply front and back labels for a cost-effective and versatile solution. It is suitable for linear labelling applications and offers excellent label adherence.

Key Features to Consider

When choosing a double side sticker labelling machine, there are several key features to consider. These features ensure the machine meets your specific requirements and provides optimal performance. Let’s explore some important features:

5.1 PLC and Touch Screen Control

A double side sticker labelling machine equipped with PLC and touch screen control allows for easy operation and precise control of the labelling process. This feature ensures accuracy and consistency in label placement.

5.2 Automatic Length Checking

Automatic length checking is a crucial feature that ensures the labels are the correct size for the product. This feature eliminates the risk of using incorrect label sizes and helps maintain the overall quality of the labelled products.

5.3 Warning Devices

Double side sticker labelling machines equipped with warning devices for insufficient or broken labels are essential to maintain the efficiency of the labelling process. These devices alert the operator when there is an issue, minimizing downtime and preventing wastage.

5.4 No Product, No Labeling

The “no product, no labelling” feature is a valuable addition to any double side sticker labelling machine. This feature ensures that labels are only applied when a product is present, eliminating the chances of mislabeling or wastage.

5.5 Servo Motor Control

Double side sticker labelling machines with servo motor control offer precise and stable labelling. This feature allows for accurate label placement, even at high speeds, resulting in consistent and professional-looking labels.

6. Suitable Products for Double Side Sticker Labelling Machines

Double side sticker labelling machines are suitable for a wide range of products across various industries. Let’s explore some specific applications:

6.1 Beverage Packaging

In the beverage industry, double side sticker labelling machines are used to label bottles, cans, and jars. Whether it’s water, soft drinks, juices, or alcoholic beverages like whiskey, rum, and vodka, these machines ensure accurate front and back labelling, enhancing brand visibility and compliance with labelling regulations.

6.2 Lubricants and Agrochemicals

Double side sticker labelling machines are also widely used in the lubricants and agrochemicals industry. These machines can efficiently label containers of different shapes and sizes, ensuring proper identification and compliance with safety regulations.

6.3 Pharma and Cosmetics

In the pharmaceutical and cosmetics industries, accurate and precise labelling is of utmost importance. Double side sticker labelling machines can handle various types of packaging, including bottles, jars, containers, and tubes. They ensure proper product identification, dosage information, and branding details.

6.4 Personal Care Products

Personal care products, such as shampoos, lotions, and creams, often require front and back labelling for regulatory compliance and branding purposes. Double side sticker labelling machines offer a reliable solution for accurate and efficient labelling of these products.

7. Factors to Consider When Choosing a Double Side Sticker Labelling Machine

Choosing the right double side sticker labelling machine for your specific needs requires careful consideration of various factors. Here are some key factors to keep in mind:

7.1 Speed and Efficiency

The speed and efficiency of a double side sticker labelling machine are crucial for high-volume production. Consider the labelling speed and the machine’s capacity to handle your anticipated production rates.

7.2 Label Placement Accuracy

Accurate label placement is essential for maintaining the quality and appearance of your products. Look for machines that offer advanced features like automatic length checking and servo motor control to ensure precise label placement.

7.3 Product Handling Capabilities

Different products require different handling mechanisms. Ensure that the double side sticker labelling machine you choose can handle the shape, size, and material of your products effectively. Consider features like belt orientation systems for seamless product handling.

8. Maintenance and After-Sales Service

Regular maintenance and prompt after-sales service are crucial for the smooth operation of your double side sticker labelling machine. Choose a manufacturer who offers comprehensive support, including spare parts availability, service, and maintenance assistance, to ensure minimal downtime and maximum productivity.

9. Conclusion

Double side sticker labelling machines are revolutionizing the labelling process across various industries. With their enhanced efficiency, flexibility, and accurate label placement, these machines offer a reliable solution for front and back labelling of bottles, containers, and jars. By considering key features, suitable products, and maintenance requirements, you can choose the right double side sticker labelling machine for your specific needs.

Explore Worldpack Automation Systems for cutting-edge Double Side Sticker Labelling Machines, transforming labelling with efficiency and precision. Choose the right solution to enhance productivity and brand visibility.

Contact us for more information.