In the fast-paced world of non stop labeling solutions, the splicer unit emerges as a true game-changer. As an industry leader, our team has over 25 years of experience, we have witnessed firsthand how this innovative technology has transformed the way businesses tackle label roll changes seamlessly. Join us as we delve into the specifics of Worldpack’s splicer unit, exploring their remarkable features and the benefits they bring to diverse industries.

The Splicer Unit’s Potential

A splicer unit is a marvel of engineering that addresses one of the most common challenges in labeling – downtime during label roll changes. As we all know, every second counts in production, and these cutting-edge units ensure that every precious moment is optimized to its fullest potential.

Customized Non Stop Labeling Solutions: A Hallmark of Worldpack

Our constant drive for perfection and the ongoing upgrades to our technology resulted in creating the non stop labeling-splicer unit. This new unit reflects our expertise and dedication to excellence.

30 Meters per Minute Operational Speed for Enhanced Productivity

The system boasts a remarkable maximum operational speed of 30 meters per minute. This impressive capacity not only ensures efficient task completion but also enhances productivity across a range of applications. Whether applied to industrial processes or logistical operations, its dependable performance at this speed substantially streamlines workflows, making it a valuable asset in diverse scenarios.

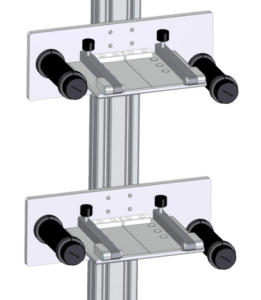

The Dual Splicing Station: An Operator’s Best Ally

One standout feature of this splicer unit is its dual splicing station. This smart feature lets the operator easily connect the new material with the one already running, saving time that would otherwise be spent on tiresome roll changes. With one station ready while the other is in use, productivity goes up, and operational efficiency reaches new levels.

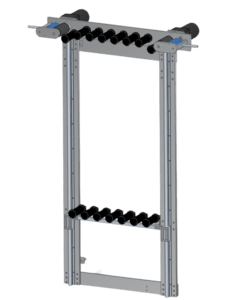

Sliding Buffer Roller System for Flawless Labeling

Reliable performance is a hallmark of the splicer unit, thanks to its sturdy aluminum extrusion structure and use of top-notch components. The sliding buffer roller system keeps labels secure and dust-free by maintaining constant tension. Such attention to detail guarantees flawless labeling, ensuring you deliver products of the highest quality.

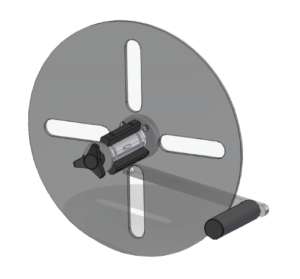

Our Expandable Unwinder: Redefining Efficiency in Labeling

Discover a new era of label roll management with Worldpack’s Expandable Unwinder. Our revolutionary design features a variable diameter mechanism, ensuring swift and seamless roll changes. Say goodbye to downtime and hello to uninterrupted productivity.

Advantages:

- Rapid Roll Changes: Adjust the diameter effortlessly for quick roll replacements.

- Boosted Efficiency: Minimize machine downtime, maximizing overall output.

- Seamless Integration: Easily fits into your current setup for instant improvements.

- Precision Engineering: Reliable performance, built to withstand continuous operation.

Embracing Versatility: Integrating with Any Labeling Machine

Adaptability is key, my fellow labelers, and the non stop labeling from Worldpack understands this perfectly. It fits with any label machine, super flexible, perfect for different industries. Now, you can upgrade your existing equipment without any hassle, taking your labeling process to the next level.

The Power of Technology: A Swift Changeover

Time is money, and with the WPM-SPLICER, you save both. Its swift changeover time of maximum 30 seconds reduces production downtime, unlocking unparalleled line efficiency. Embrace this technology, and watch your production soar while eliminating the stoppages that hinder your progress.

Conclusion: A Leap Towards the Future

As a veteran in the labelling industry, We are thrilled to witness the rapid advancements brought forth by the splicer unit. Its transformative impact on production efficiency, reduced downtime, and seamless integration with existing machinery exemplifies innovation at its finest.