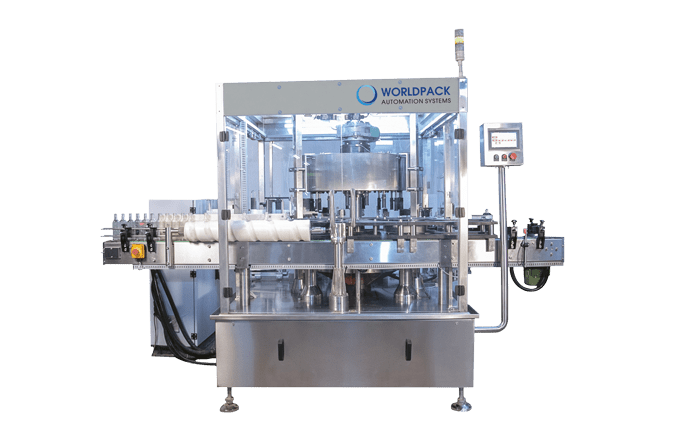

Experience the precision engineering and build quality

Our Rotary labelers are designed keeping in view the challenging applications of label orientation w.r.t. logo embedded on premium brand liquor and beverages bottles.

The labeler applies label with great accuracy at the desired location on bottles without any manual intervention. Multiple labeling heads can apply upto 3 labels on bottles including neck label.

See our precision-engineered labelling solution designed for reliability, efficiency, and seamless integration into your production line.

WorldPack Quality: Professional grade manufacturing with rigorous testing ensures consistent performance in industrial environments.

Contact our team to discuss your labelling requirements and get a customized quote.