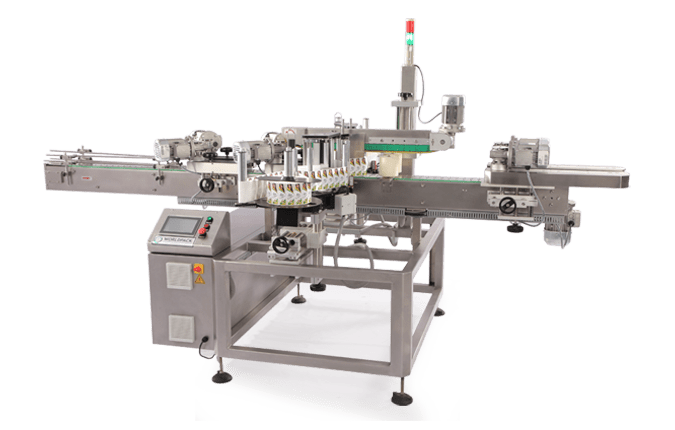

Front and Back Labelling Machine

Our automated front and back labelling machines are extremely durable, efficient and easy to operate. This front & back labeller can be installed quickly and contains no change parts to be adjusted providing easy operations and low maintenance. Equipped with intelligent technology, Worldpack front and back labelling machines labellers can label up to 300 bottles per minute. The labeller system comes equipped with a colour touch-screen for easy accessibility. The precise technology used to design the labeller makes sure that the labelling is precise on single side and double side even when executed simultaneously on different types and shapes of products. The synchronised VFDs make it possible to adjust the labeller’s speed providing single point control. The device also remains secure with a 3 level password protection.

Applications

Technical Specifications

| SPEED | : | 60 TO 300 BPM |

| ROLL O.D. | : | 300MM |

| LABEL MATERIAL | : | PAPER / FILM / PP / PE |

| MOC | : | SS 304 |

| POWER SUPPLY | : | 220 / 50HZ |

| POWER CONSUMPTION | : | 3KVA |

| OPERATING SYSTEM | : | MICRO CONTROLLER BASED / STEPPER PLC / SERVO PLC |

| MACHINE SIZE | : | 2500MM X 2000MM X 1800MM (LXBXH) |

| WEIGHT | : | 350KGS |

| PRINTER | : | TIJ / TTO / CIJ CAN BE INTEGRATED WITH THE MACHINE SHROUD OPTIONAL |

STANDARD FEATURES

-

No change parts

No change parts -

Product count

Product count -

3 level password protection

3 level password protection -

Synchronized VFDS for single point control

Synchronized VFDS for single point control -

Precise labelling of single side or double side simultaneously on various types and shapes of containers

Precise labelling of single side or double side simultaneously on various types and shapes of containers -

Color touch screen for easy accessibility

Color touch screen for easy accessibility

OPTIONAL FEATURES

-

Safety cabinet with interlocks

Safety cabinet with interlocks -

Electrical panel door interlock

Electrical panel door interlock -

Toppled bottle detection system

Toppled bottle detection system -

Label roll end alarm

Label roll end alarm -

Jamming sensor

Jamming sensor