Understanding the Labeling Machine for Bottles

Efficiency is essential in contemporary production and packaging. When it comes to labeling bottles, the usage of an automatic labeling machine is a game changer. This innovative technology not only speeds up the labeling process but also provides precision and uniformity in labeling, which helps to improve a brand’s image and compliance with labeling standards.

How Labeling Machines for Bottles Work

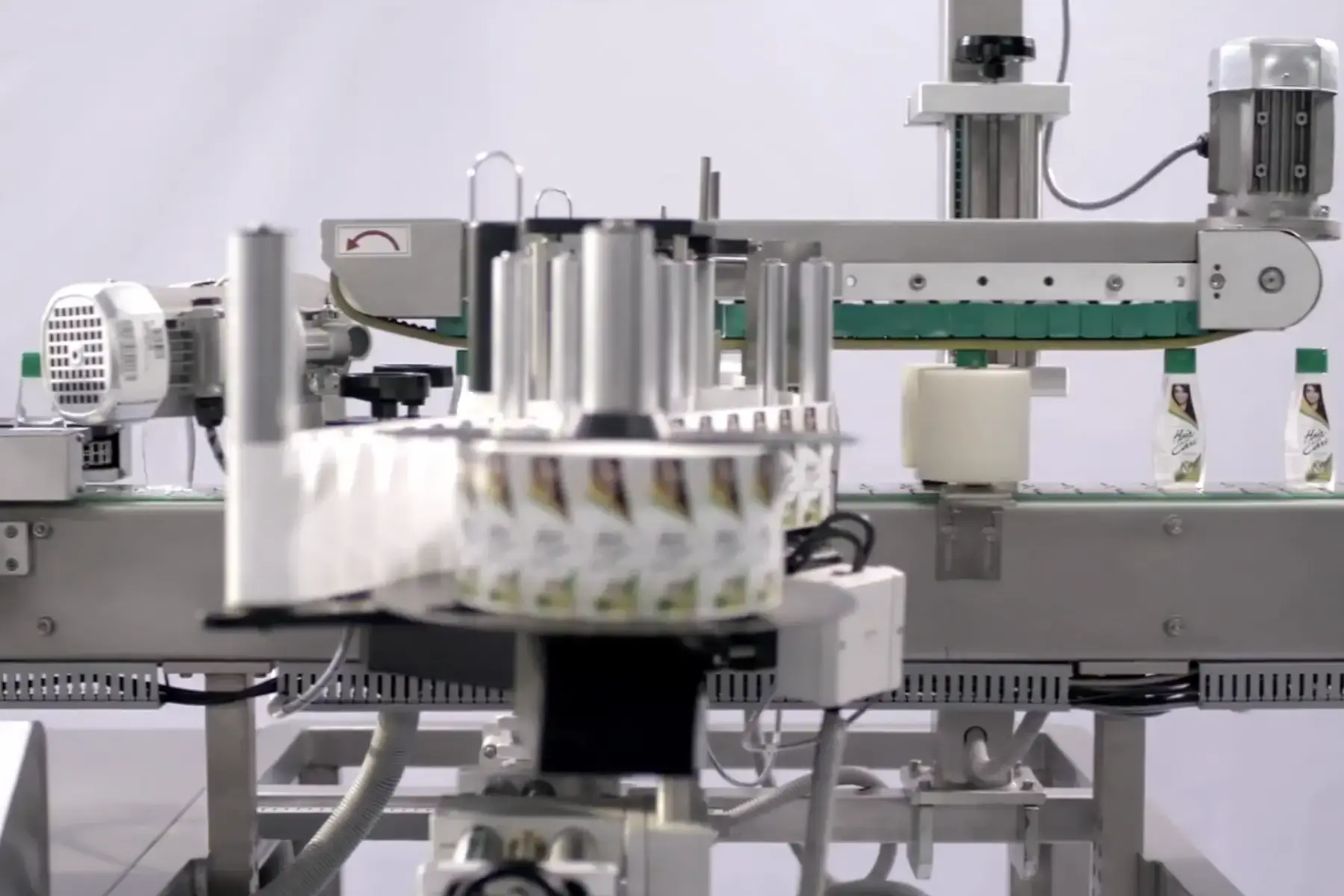

Bottle sticker labeling machines are automated systems that apply labels to various types and sizes of bottles correctly and effectively. To achieve perfect label placement, these machines employ a variety of devices such as conveyor belts, sensors, label applicators, and, in some cases, vision systems.

To learn more, watch the video.

Benefits of Using Labeling Machine for Bottles

In today’s world of manufacturing, technology is key to success. Labeling machines are one such technology that is making a big difference in bottle labeling. They offer several benefits that make production faster, more accurate, cost-effective, and adaptable.

1. Super Speed Labeling:

Automatic sticker labeling machine for bottles outperform humans in terms of speed. They can put labels on bottles considerably faster, which implies they can make stuff faster. This allows factories to generate additional products in less time.

2. Perfectly Accurate Labels:

These machines consistently place labels in the correct location. It ensures that every bottle looks the same, which is critical for branding. Customers are more likely to trust a brand when they see an identical label on every bottle.

3. Saving Money with Less Workers:

Because automatic sticker labeling machines are used, a manufacturer does not require as many workers to apply labels to bottles. This saves money in the long term since there are fewer paychecks to distribute. Furthermore, there are fewer errors, which can cost money.

4. Fits All Kinds of Bottles:

Bottles occur in a variety of forms and sizes, particularly in businesses such as medicine and beverages. Sticker labeler machine can easily handle all of these distinct bottles. This makes them valuable in a variety of industries.

Types of Labeling Machines for Bottles

1. Wrap-Around Labelers:

When a company wants to make a strong statement with its packaging, wrap-around labelers are the ideal option. These devices apply labels that completely round the bottle, providing a 360-degree canvas for brand awareness. This not only gives you more room to display important details and eye-catching visuals, but it also makes sure that your brand is visible from any aspect. It’s a great option for goods like high-end drinks or designer cosmetics where branding and aesthetics matter a lot.

2. Front and Back Labelers:

When a bottle needs information on both sides, front and back labelers can help. They can concurrently apply labels to the front and back of bottles, making them akin to the multitaskers of the labeling industry. For items like wine bottles, where branding and regulatory information must be seen from a variety of perspectives, this adaptability is extremely useful. While adhering to labeling rules, front and rear labelers make sure that your product appears from every angle.

3. Top Labelers:

Top labelers come into play when you want to leave a memorable impression. These devices are experts at adding labels on bottles’ top surfaces, which is a popular choice for food, cosmetics, personal care, and pharma products. It provides a distinctive and fashionable presentation in addition to providing options for original branding.

4. Shrink Sleeve Labelers:

Labelers of shrink sleeves are similar to bottle labeling machines. They attach labels that, when heated, closely follow the contours of the bottle. This meets functional needs in addition to producing a beautiful aesthetic. Since shrink sleeves have plenty of room for attractive images and product details, they are frequently utilized in marketing. Additionally, they provide tamper-evident packaging to guarantee the integrity and safety of the goods for customers.

Industries Harnessing the Power of Labeling Machines for Bottles labeling machines are used throughout sectors in the context of production and product packaging. These instruments are considerably more than just mechanical tools; they play a crucial role in maintaining accuracy, quality, and branding in a variety of industries.

Fields where these automated machines are essential:

1. The Beverage Industry

The efficiency of labeling equipment is crucial to the beverage business. These devices are responsible for the clean look and clear labeling on bottles that contain pleasant liquids like water, soda, or painstakingly created beverages like beer. They ensure that each bottle is a testament to quality and consistency by conveying the essence of the product in addition to applying brand insignias.

2. Pharmaceutical Industry

Precision in the pharmaceutical industry is essential. Medicines are lifesaving tools, thus packing must be exact. Labeling machines are essential for attaching important information including dosage guidelines, safety precautions, and expiration dates. This accuracy is crucial for adhering to strict regulatory standards as well as for patient safety.

3. Food Industry

Think about the common sight of a jar of your favorite jam or a bottle of ketchup. Packaging plays a crucial role in the gastronomic experience in the food sector. The designers of this experience are the labeling machines, who make sure that the labels not only tempt the taste senses but also adhere to strict quality and safety regulations. These machines make sure that every label accurately captures the spirit of the product within, whether it be handmade jams or widely known sauces.

4. Cosmetics and Personal Care

Form and function go hand in hand in the world of cosmetics and personal care. The cosmetics industry depends on labeling machines to apply labels that seamlessly combine aesthetics and functionality, whether it’s a stylish perfume bottle or a accurately labeled shampoo container. These labeling machines make sure that labels are both aesthetically pleasing and informative, boosting customer trust and brand loyalty.

Bottle sticker labelling machine appears as stealth sentinels of effectiveness, precision, and quality in each of these sectors. They are the essential components putting a lot of effort into the background to make sure that the bottles we meet regularly are not only containers but also storytellers. These stories provide order, knowledge, and refinement to our world while speaking of flavor, health, sustenance, and beauty.

How to Choose the Right Labeling Machine for Bottles

Choosing the Right Labeling Machine for Bottles

When it comes to labeling bottles efficiently and accurately, selecting the right labeling machine is crucial. Here are some key factors to consider:

- Bottle Type and Size: Choose the kind of bottles that you’ll be labeling. Make sure the machine you choose can handle your bottles properly because different machines are made for different bottle shapes and sizes.

- Label Material: Consider the type of labels you’ll be using. When selecting labels, ensure compatibility with your labeling machine; paper may work better with some machines, while others may be better suited for plastic or vinyl labels.

- Label Placement: Consider where you want the labels on the bottles to go. Machines vary in how flexible they are when it comes to label placement.

- Speed and Capacity: Analyse your demand for production. Choose a labeling machine that meets your production volume as speed and capacity vary.

- Automation Level: Choose the level of automation you want for the labeling procedure. There are manual, somewhat automatic, and completely automatic labeling devices. Efficiency and labor needs will be impacted by the extent of automation.

- Budget: An important consideration is your budget. Select a labeling machine that aligns with your budget since their prices can vary. Feel free to reach out to us for guidance on this matter.

- Ease of Use and Maintenance: Take into account how simple it is to install, run, and maintain the machine. A machine that is simple to use can speed up operations and ease operator training.

- Additional Features: Some labeling machines include supplementary functionality like built-in printers, date coders, or quality control vision systems. Consider whether these characteristics are necessary for your labeling procedure.

- Supplier Reputation: Research the reputation of the manufacturer or supplier. Read reviews, check for warranties, and ensure good customer support in case you encounter issues.

- Future Expansion: Think about your business’s growth potential. Choosing a labeling machine that can adapt to increased production needs can save you from having to upgrade too soon.

Efficiency, precision, and compliance are critical in a manufacturing industry. A bottle labeling machine is an investment in the success and reputation of your business, not just a piece of machinery. By utilizing this technology, you can make sure that your bottles are accurately and consistently labeled, differentiating your products in the market.

WORLDPACK Machines – One-Stop Shop for Labeling Solutions

If you’re in need of machines like these, please don’t hesitate to reach out to us. We would be more than happy to assist you in finding the right labeling machine that suits your specific requirements and budget. Our team is here to provide you with expert guidance and help you make an informed decision.