In today’s fast-paced production environments, selecting an optimised label applicator is crucial for efficiency and accuracy. Worldpack Automation Systems, a leader in labelling solutions, understands the importance of matching the right labelling machine to your specific needs. Here are details of key considerations :

Critical Factors for Label Applicator Selection:

Worldpack Automation Systems emphasizes the following factors when choosing an automatic labelling solution:

Product and Label Specifications:

Product Shape and MOC:

- Is your product a cylindrical/flat/square oval bottle, or an irregularly shaped Bottles?

- Is it made of glass, plastic, or metal? Worldpack offers solutions for diverse materials.

Variety of Label Material and Sizes :

- Ensure the applicator can handle your label width and length.

- Consider the label material (paper, PE, PP, PET film, etc.) and its compatibility with the applicator. Worldpack systems offers labelling solution for different label materials.

Labelling Application Type:

Worldpack offers solutions for:

- Front and back labelling.

- Wrap-around labelling.

- Top Labelling.

- Print and apply labelling.

- Hologram Applicator.

Production and Operational Requirements:

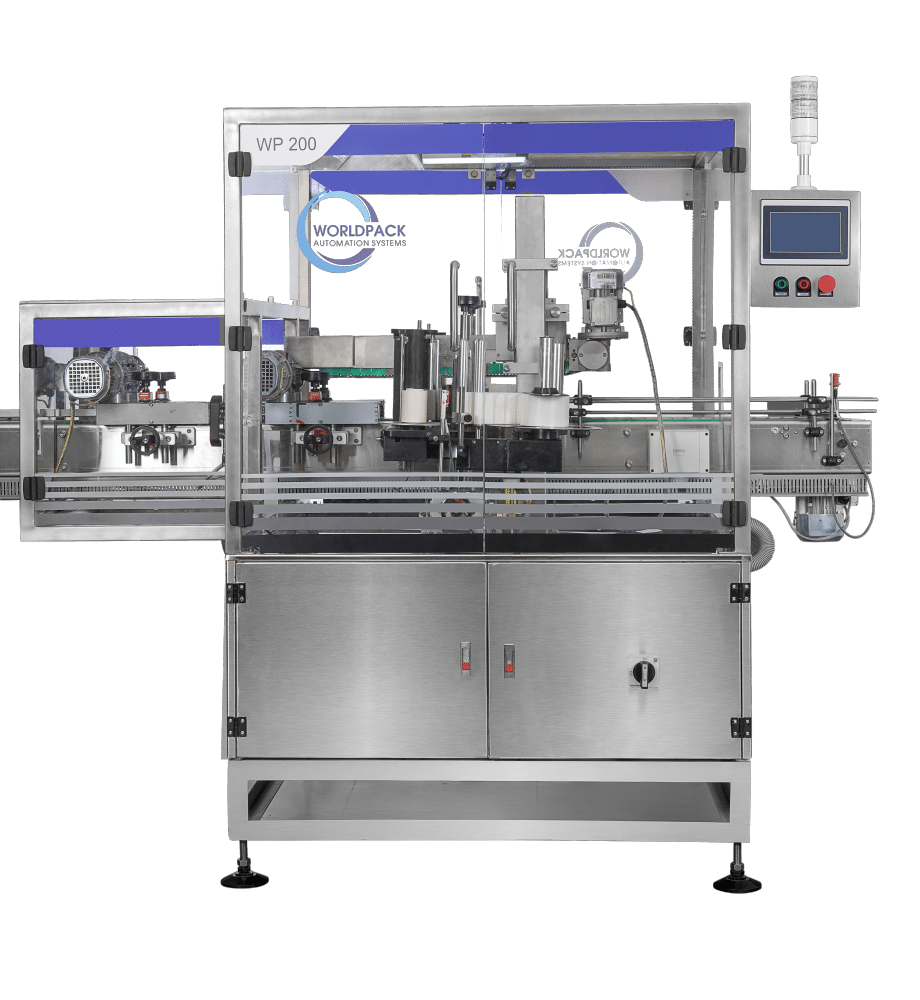

- Production line Speed: Match the applicator’s speed to your production line’s output. Worldpack machines can achieve high-speed labelling (60 to 800 BPM).

- Accuracy and Consistency: Precise label placement is essential. Worldpack’s systems are designed for labelling accuracy and precision.

- Integration and Automation: Wondering how the applicator will integrate with your existing production line. Worldpack systems have a solution for integration into automated line.

- Operational Control: Worldpack machines have advance features like colour touch screen interfaces, and password protection to ensure easy use, and security.

Advanced Features and Options:

Print and Apply Functionality:

- For variable data labelling, Worldpack offers print and apply solutions.

Inspection and Rejection Systems:

- Optional features like vision systems for barcode verification and rejection systems for faulty labels enhance quality control.

Safety Features:

- Safety interlocks, and other safety features are available.

Worldpack Automation Systems’ Strengths:

- Worldpack focuses on providing durable and efficient labelling solutions.

- Our machines are designed for ease of operation and low maintenance.

- We provide semi automatic, and automatic labelling machines.

- We have a wide range of machines able to provide many different labelling applications.

Key Considerations from Worldpack:

- “We analyse the customer’s needs.”

- “We design dedicated solutions.”

- “We deliver comprehensive solutions on time.”

- “We guarantee fast service.”

By carefully evaluating these factors and partnering with a reputable provider like Worldpack Automation Systems, you can ensure a smooth and efficient labelling process.

🌎 Worldpack Automation Systems.

📩contact@worldpackmachines.com